Over the last few decades, technology has been induced in the supply chain, resulting in remarkable changes in costs and performance. What disruptive technology have you adopted in your supply chain? If the answer is none, it is time to know that you are operating in the ’50s, missing numerous business opportunities, and chances are that you are alone in that analogue jungle.

What Disruptive Technology Have You Adopted?

Most supply chains across the world have adopted at least one of the disruptive technologies in the market, to try to keep them afloat in the ever-competitive business environment that the word has become – a global village. The market today has got so much you can choose from, there are those which have gained tremendous popularity like cloud computing and the internet of things. Others that are on the horizon include big data, artificial intelligence, 3D printing, and many more.

This article should be an eye-opener for you; to have an insight into what the market is offering and choose from there, what will work best for your supply chain. Follow through.

- Cloud Computing

Cloud computing

This is a disruptive information technology model that allows you to access and store programs and data over the internet rather than over the traditional server system. The model allows expedient on-demand network access to a pool of data with minimal human interaction or management effort.

Cloud computing is basically of three types: private, public, community, and hybrid cloud computing.

Any benefits of cloud computing to the supply chain? Yes, uncountable benefits! Efficiency, cost reduction, growth and scalability, speedy access are just but a few.

- Internet of Things

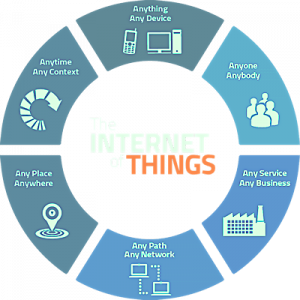

The internet of things (IoT) is a computing concept where physical devices (smartphones, sensors, smartwatches, and even wearables) are connected to the internet and to each other to enhance information transfer and sharing.

It is a computing system where connected devices, digital machines, and even people are assigned unique identifiers and the ability to share data without human interactions.

It looks into the possibility of making the world one big information system by connecting anything and enabling it to communicate intelligently. As one internet guru – Caroline Gorski said, “It’s about the device, it’s about data, and it’s about networks”

Supply chains that will adopt the internet of things are assured of curbing catastrophes and avoiding disruptions in a big way. Looking at various calamities that have been happening around the world – bridges collapsing under heavyweight, ferries sinking in the ocean, trucks causing accidents due to unfavorable weather conditions, and many more – all of which adversely affect supply chains in general and the transport sector in particular. The internet of things will amicably solve such issues. You are already asking how, yes? Look at the possibility of manufacturing a ferry with smart steel such that in case the ferry is overloaded, the steel will send a signal to the operator before leaving the dock. The transport trucks can also be fitted with or made of smart materials that will detect any unfavorable weather conditions, like fog and notify the driver in advance – turning information into action. How about building the bridges with smart cement and steel which will give the same signals? Does it sound like magic? Well, that is what technology is meant to be; as one Arthur C Clarke opined, “Any sufficiently advanced technology is equivalent to magic”

Some of the benefits of IoT include improved customer experience, enhanced employee productivity, improved communication, and costs saving, among others.

- Simulation Tools and Models

Technology advancement has enabled supply chains to use simulation modelling in logistics planning and optimization, warehouse management, supply chain designing, and transport, among other areas.

The simulation tools and models enable supply chains to reduce costs, manage challenges optimally, and enhance service delivery levels.

- Augmented Reality (AR)

Augmented reality is superbly changing the contemporary supply chains. This technology has been adopted by major supply chains in their warehousing, transportation, and customer service, among others.

In the warehouse, AR is digitizing processes like receiving goods, offloading the goods and physical counting, sorting and arranging them, order picking, and maintaining accurate records.

Transport has also been made easier using AR technology. With the AR software, you do not need the traditional cargo listing or the manual tracking systems. The AR can track the cargo for you from loading to delivery. Additionally, the application can give you such details as the consignment weight, price, and size. Customers who have the system can not only track their cargo but also get real-time information about any replacements and refunds.

In maintenance, AR is very instrumental in fault detection and rectification in machines. With the AR glasses, you can easily inspect your machine and identify any structural or mechanical problem, which enables quick fixing, therefore, avoiding delays in the supply chain. Besides, AR-powered glasses can provide instructions to fix and repair any mechanical error with the help of live tutorials and how-to videos.

The technology mainly uses smart glasses and AR devices to maintain real-time inventory information, eliminate human error, and achieve a high level of efficiency.

- RFID

Radiofrequency identification (RFID) is a technology where you are required to have RFID chips for your inventory, indicating the location and movements of materials and items in the warehouse, stores and every other connected read point.

RFID is effective in inventory management, which results in reduced costs of inventory holding (pilferages, storage, among others). Think of a situation where with the help of RFID you can have smart cabinets that will enable you to have full visibility of your inventory. This visibility will help you know what is in stock, when to replenish, and how much to order. With this kind of technology, you are bound to magnificently reduce the costs associated with inventory holding mentioned above.

RFID hit the market and fizzled sooner due to the high cost of RFID sensors and the low level of technology uptake in retail stores back then. The technology is now coming back since the costs have gone down and retail stores are adopting technology faster.

- Smart Sensor Technology

Smart sensor technology is just that – the use of smart sensors that give consistent, predictable and measurable feedback on the physical processes. Unlike the traditional sensors, the smart sensors have microprocessors and storage tools that convert the classical feedback signals into contemporary digital ones.

The benefits that come with smart sensor technology include improved customer experience, better demand planning, and cost reduction.

- 3D Printing

3D printing – also known as additive manufacturing – is a disruptive technology where a 3D printer is given a set of instructions to read a digital blueprint and produce a product. It is manufacturing products from a digital file.

3D printing is suitable for a company that has a complete supply chain – production, warehousing, assembly, stores, and transport. If you are in e-commerce and only need a website and some internet connection, 3D is not meant for you.

With this technology, you can implement inventory management strategies like just-in-time (JIT) which impeccably reduce inventory holding costs. You can, therefore, do away with the mass production, which goes hand in hand with standardization, and instead promote the production of customized items.

With this technology, you can implement inventory management strategies like just-in-time (JIT) which impeccably reduce inventory holding costs. You can, therefore, do away with the mass production, which goes hand in hand with standardization, and instead promote the production of customized items.

It also uses fewer materials and has less waste, reducing production costs and waste disposal costs. You can also reduce lead times considerably, which will make you more responsive and, therefore, deliver better customer service.

Many have seen 3D technology as the next industrial revolution, with projections that very soon firms will be able to print products as complex as buildings. Sounds unbelievable huh? It should not, already products like doors, walls, and floors. It is, therefore, possible to print a complete building. The future of the construction industry seems to lie in 3D printing technology.

- Artificial Intelligence

Artificial intelligence or machine learning as popularly known is the next big transformation in the supply chain. This is simulating human intelligence using computers. The basic principle of AI is the ability to identify patterns across the velocity, volume, and variety of big data and then find correlations among the diverse data

Due to the nature of the data collected and analyzed in the supply chain (huge volumes of structured and unstructured data), artificial intelligence becomes ideal.

The benefits of this technology include speed and accuracy.

- Robotics

Robotics is driving value in the supply chain in an implausible way. Due to the simplicity and monotony of the tasks in the supply chain, the use of robots is becoming popular each day, for instance, the movement of materials in the warehouse which requires little skill. This reduces the costs associated with human labor like wages, pilferages, insurance, and human errors. Transport companies are swiftly adopting the use of automated trucks and drones, which are more efficient than traditional transport means.

Robotics is driving value in the supply chain in an implausible way. Due to the simplicity and monotony of the tasks in the supply chain, the use of robots is becoming popular each day, for instance, the movement of materials in the warehouse which requires little skill. This reduces the costs associated with human labor like wages, pilferages, insurance, and human errors. Transport companies are swiftly adopting the use of automated trucks and drones, which are more efficient than traditional transport means.

Unlike the use of human labor, robotics’ performance has got zero defects and improved productivity. Think of a robot working for hours without asking for overtime, leave or work shifts. This technology can work perfectly in delivery vans, parcel sorting hubs, and distribution centers.

Warehouse managers can use robots in automated or self-driving vehicles that replace conveyors and large vehicles, therefore, reducing costs further.

Parting Shot!

Digitalization is the single biggest change creator in the modern supply chain. For competitiveness, improved performance, reduced costs, you have to relook at your technology uptake.

You should, however, not go for technology for the sake of ticking the box. Take your time to select what will bring your organization a remarkable change.

Check out on our next article which will give more insight into each of the disruptive technologies, how each works, potential benefits, and challenges of disruptive technologies.