Today more than ever, to face increasing global competition, reduced customer loyalty and pressure on margins, we need to be ahead of the pack in term of product or service development… and fast. That is why organisations focus on their “time-to-market” capability defined as the period between the first ideas around a product/service and its availability on the market.

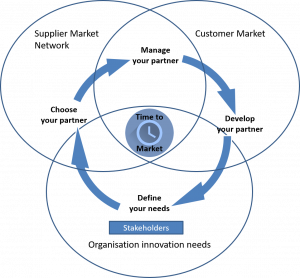

Multiple studies and literature have been written on this subject with several of them mentioning the potential that represents an organisation’s supplier network to improve innovation capability without however, describing ways to tap into it. The present article suggests an approach to identify what it is needed from your suppliers to boost your time to Market and how to choose, manage and develop these suppliers.

1- Time to market concerns all industries and technologies.

Reducing time to market is obvious when talking about electronic consumer products like cellphones or gaming systems, but it applies also in other sectors because as markets are less and less local and more global, organisations are exposed to a wider range of existing and potential competitors.

A survey1 done in 2018 by the firm Jabil in the automotive industry showed that the majority of the respondents (78%) claim that their efforts to reduce their time to market timeline have been mainly triggered because of new industry players entering in the market, and 29% of them evaluated that while the timelines have shortened in the last 5 years, they should be further reduced in the next 5 years! To achieve this, they identified several drivers among which, advances in technology (53%), improvement in Supply Chain efficiency (41%) and development of partnership with expert suppliers/partners (36%) are the main ones.

While this survey covers only the automotive industry, this situation is similar or can be even more important in other industry sectors.

2- We innovate but we have limited resources and time to make it happen!

Organisations must reduce their time to market without jeopardizing quality while creating real breakthrough innovations. Many organisations will choose to “revamp” an existing product or service instead of going for something more innovative in order to provide a product/service on the market with some improvement, rapidly, while reducing their risks and minimising their financial and resource investments.

Preston G. Smith in his book “Flexible Product Development”2 referring to a study made in 20052 showing changes in the product portfolios of a broad selection of companies from 1990 to 2004, mentioned that “There has been a steep decline in highly innovative new-to-the-world products, and this gap has been filled by an 80 percent increase in low-innovation improvements and modifications to existing products”.

The author mentioned that one strong factor to explain this, is related to “pressure from the financial markets that have driven industry managers to be overly conservative — make no mistakes!” Consequently, they have established development systems that reduce variation, waste or uncertainty (i.e.: Six Sigma, Lean, Stage-Gate®). “Although such systems have been successful in other parts of the business…, they have had the unfortunate side effect of inducing rigor mortis in product development activities for the more volatile one [where] developers need more flexibility to make midstream changes.” According to M. Smith, these midstream changes are from different origins. One of these originates from the supplier network. “As very few companies today develop a product entirely by themselves, they use suppliers who are expert in a particular area or provide specifics components. These suppliers/partners tend to be located in distant parts of the world. Which create a fertile ground for changes.2”. Changes can also originate from a supplier/partner that is overloaded or does not have enough expertise.

3- Faster innovation is great.., if more customers adopt it!

As the economy is more and more global, the consumer adoption rate becomes another factor to consider as it may become a roadblock for a sustainable production.

In the context of the globalization we are facing today, any company wishing to ensure its sustainability must be able to strengthen its ability to become more global as quickly as possible.

On a study3 prepared for the 8th Global Conference on Business & Economics in October 2008 Gianpaolo Baronchelli and Fabio Cassia, identified seven factors “that drive companies choice towards the global approach […].”:

a. Uncertainty and dynamism in the firm’s environment

b. The home market

c. Industry and segment

d. Knowledge availability

e. Firm’s entrepreneur and management previous experience

f. Firm’s innovativeness and innovation skills

g. Network links

While all these factors are important enablers, developing strong network links is an important element in helping an organisation to improve its time-to-market efficiency and reduce the associated risks.

4- Increasing the size of your market only by your own?

Network links are particularly interesting here as it is associated also to the suppliers’ network mentioned earlier by Preston G Smith as well as in the Jabil’s survey. Baronchelli and Cassia in their study, mentioned that “Networks and partnerships are fundamental resources for successful international new ventures.”3,4,5,6,7,8 “[…] Therefore [it] is important to build trustful suppliers’ networks, bond by real and long term partnerships that will help the company to start new projects with suppliers “inside” the group, from product development to bulk production and delivery to company warehouse.”3

5- The importance of an appropriate supplier network

An organisation that has an appropriate suppliers/partner network has more possibilities to:

- reduce internal R&D resources by using the supplier’s ones

- reduce risks by using the technical and the market expertise of its suppliers/partners

- reduce development time and avoid “reinventing the wheel”

- reduce the investment as some suppliers already went through the necessary learning curve

- reduce total cost of ownership

- allow outsourcing of non-core activities to focus on main expertise.

- allow taking benefit from an existing network using the knowledge of the suppliers in the targeted markets.

6- Use your supplier network properly and efficiently: move from the order management era to the information management one

Although it seems attractive, it is challenging, and many organizations fail by underestimating the required internal change management effort.

In fact it is a radical change. It requires a different approach in defining the needs our suppliers will have to fulfil and in the way we select, manage and develop them.

7- Define the needs not just the price!

Usually when we are talking about communicating needs to a supplier, the first things that come to our mind are the technical specifications/scope of work, the quantity and the price of the component/service we want to purchase. But in the context we are talking here, this way of doing is not sufficient as many other elements need to be taken into consideration:

- Sometime the specifications are not even known or only partially known and you will need a partner who can define them with you or for you, using its expertise or experience in similar projects. This means that at the beginning of the project at least, expertise and experience are more important than establishing a cost per part.

- You might have some weaknesses (for example in a specific technology or in project management or in prototyping) that can be compensated by your partners

- In some case the alignment with some critical elements of the company’ strategy will be essential:

- HR: You need a partner that can provide temporarily specific R&D resources

- Operations: you need to outsource non-core activities to keep the focus on your core business.

- Marketing: you will prefer to obtain specific “hands on” market information from someone else than a consulting marketing firm.

- Financial: you want to share the investments and the risks of the project.

- Culture: Trust might be of the essence here as you would have to share some very sensitive information on both sides, manage many changes and deal with several unknown elements during the execution of a project, requesting a very strong cultural fit between both organizations.

- A rigorous market analysis to validate the capability of the suppliers will also be essential as if the capacity nor the expertise do not exist, your needs will have to be revaluated.

- It will require also a fair and honest evaluation of the internal strength and weaknesses of your organization. Being aware of such will be essential to know what a future partner should bring to the table.

- Openness from the top management will also be required:

- To allow a fair and honest evaluation of the internal strength and weaknesses of your organization.

- To look outside of the box to test some new ideas as well as consider “non-traditional” suppliers market to stimulate or accelerate innovation.

These elements cannot just be expressed in a “wish list”. It needs to be formalized, weighted and included in your needs definition, with all the stakeholders, as the contribution of your partner in such development projects, will not be only to eventually provide a component or a service, but to accelerate your time to market by compensating your weaknesses or your lack of knowledge.

8- You are not just launching an RFQ you are choosing an innovation partner!

The selection criteria you will use to choose your partner should then be based on these needs.

These criteria will probably be more difficult to evaluate and it will not be a matter of just simply inviting your suppliers to fill a RFQ form in your eSourcing platform to compare their proposals that will allow you to select your partner. You will deal with many soft issues and you will probably not be able to compare apples with apples.

In addition, you will have to involve more heavily the senior management teams to explain your expectations as the outcome of this selection will require collaboration for a longer term involving a stronger commitment from the upper management of both parties.

It is quite obvious also that you will not find the “ideal partner” that will fit all your needs. You will have to consider a different approach than eliminating the non-compliant proposals and give extensive feedback to the suppliers seeking their participation to address gaps in an acceptable timeframe which in some case, will be better than starting from scratch with another round of RFQ.

9- You are not building a standard frame agreement you are building an innovation network!

The framework that will be used should also take into consideration the major success factors required to enable the required flexibility and commitment of both parties’ resources in the development process like:

- How targets will be established (financial, product performance, timing, ect..)

- How “performance” in these development projects will be measured, monitored and recognized and/or improved when necessary (cost, timing, quality of expertise, level of participation, ect..)

- How risks & responsibilities will be shared

- How the information and IP will be managed between both parties

- How changes are managed during a project

It is also a well-known fact that the majority of a product cost is determined during the design phases. The future agreement will need to enable supplier’s early involvement in the development phases integrating their knowledge, ideas and operational constraints which will all have a huge effect on the part/system cost, as well as on the time to market. This means that the future agreement will need to go well beyond what would be achieved through a traditional commercial negotiation occurring after the design completion.

The key purpose of this framework is to facilitate the management of changes that will, for sure, happen. The main challenge being, on one hand, to be faster, more flexible and creative than if you were relying only on your internal resources and expertise while, on the other hand, dealing with commercial, legal and operational constraints created by partnering with another organisation. Specific and adapted governance rules for such type of collaboration become then more crucial than any other types of partnership.

10- As any relationship you have to nurture it!

Everyone who has experience in establishing agreements know that the main challenge is not to get those agreements signed but to deploy and manage it after!

With the type of collaboration considered here, this statement is more important than ever as we are talking about a development process where changes will be the norm, where unexpected situations will be frequently encountered and where, by nature, the decisions made will have many gray areas.

Leaders involved in such projects must stimulate frequent exchanges among both parties, establish the appropriate project management approach, create and promote room for creativity, evaluate the performance and frequently give feedback about it to enable corrective actions when necessary.

They should also make room for other types of relationship with the suppliers and go beyond the typical buyer/seller’s one. For example some strategic information can be communicated sometime in an informal way and becomes very useful to influence the development of a product or the sales strategy for specific geographical area.

11- Building your external innovation network required an internal cultural shift

Many experts mentioned the importance of a strong supplier network to enhance innovation and time to market but saying it is one thing, making it happen is another.

Selecting and managing suppliers/partners to help improving the time to market efficiency is a strategic step that will require creativity and perseverance from the entire organisation and especially from top management. It will need a cultural shift as it will require, from all major involved stakeholders, honest and deep analysis of the organisation’s weaknesses regarding its innovation and time to market capability, to really identify the gaps to be fulfilled by their external partners. It will also request to adopt a new approach from the way these partners are selected to the way they will be integrated, managed and developed during any innovation activities.

| References: |

| 1 Automotive & Transportation Product Development Cycles survey from JABIL https://www.jabil.com/insights/blog-main/automotive-industry-trends-point-to-shorter-product-development-cycles.html? 2 From Flexible Product Development by Preston G. Smith, Jossey-Bass, 2007. © 2007 by John Wiley & Sons. Used with permission. Data source: Robert G. Cooper, “Your NPD Portfolio May Be Harmful to Your Business’s Health,” Visions, 29(2):22–26 (April 2005) 3 “Internationalization of the firm: stage approach vs. global approach”, ISBN : 978-0-9742114-5-9, from Gianpaolo Baronchelli and Fabio Cassia, University of Bergamo, Italy 4 “A Strategic Approach to Internationalization: a Traditional Versus a ‘Born Global’ Approach”, Journal of International Marketing, 12 (1), pp. 57-81, from Chetty S., & Campbell-Hunt, C. (2004) 5 “How Smaller Born-Global Firms Use Networks and Alliances to Overcome Constraints to Rapid Internationalization”, Journal of International Marketing, 14 (3), pp. 33-63, from Freeman, S., Edwards, R., & Schroder, B. (2006) 6 “The Globalization Strategies of Business-to-Business Technology Industry”, Industrial Marketing Management, 36, pp. 1104-1117, from Laanti, R, Gabrielsson, M., & Gabrielsson, P. (2007) 7 “The Internationalization of Born Globals: An Evolutionary Process?”, International Business Review, 6 (6), pp. 561-583, from Madsen, T. K., & Servais P. (1997) 8 “Global Start-Ups: Entrepreneurs on a Worlwide Stage”, Academy of Management Executive, 9 (2), PP. 30-44, from Oviatt, B. M., & McDougall, P. P. (1995). |